User blogs

Central Margins Review – A Shady Brokerage You Should Avoid

Despite the website being inaccessible, we managed to dig up some dirt on this fraudulent broker. We believe that the website was probably taken down due to numerous complaints. But, do not count out the possibility of this scammer reemerging. That’s why the Central Margins Review is here to ensure this broker remains at the margins. To get more news about central margins review, you can visit wikifx.com official website.

On top of that, we recommend you not invest in the fake brokers FewaTrade, OpoFinance, and TargoSwiss. Do not trade with these unlicensed brokers if you want to save your money!We instantly noticed that the shady broker provided the name of its owner and HQ. The alleged owner is Central Margins Trading Services LLC, based in SVG. When scammers pick their home, they typically go for SVG because the laws there are not rigid or strict at all. However, one thing to note is that SVG’s financial regulator does not supervise Forex trading.

Furthermore, Central Margins wouldn’t be your typical scammer without including a fake address, now would it? Geneva, Switzerland, hmmm. The financial swindler really loves these tax havens.

One thing we appreciate about CentralMargins is the lucid and honest confession about its unauthorized status. The phony even put it out straightforwardly – “Central Margins Trading Services LLC is not required to hold any financial service license…” There’s not much to add here, Central Margins is unregulated as hell and pretty dangerous.

This offshore broker carefully selects its targets. From what we gathered, the main targets of this fraudster are residents of Canada, Romania, Switzerland, and the US.

Switzerland should not come as a surprise since the scammer provided a fake Swiss address. However, it’s hard to pinpoint the correlation between US/Canada and Romania. Nevertheless, wherever you come from, avoid dealing with this dangerous provider.The illicit broker claims to have won various awards, specifically for its platform, which we already covered. That’s easy to say but where exactly are those awards and who presented them? If you were to ask Central Margins that, the cat would surely run away with the scammer’s silver tongue.

Again, we did not find information about the features of the broker’s account types. What we do know is that the minimum deposit used to be $10,000. Let us spell that out for you – T-E-N T-H-O-U-S-A-N-D D-O-L-L-A-R-S! Central Margins should be ashamed! No sane provider would dare demand such a large amount of money.

Here, our scam broker claimed to accept two classic methods of payment – credit cards and wire transfers. There’s no info on fees. Hypothetically, you’ve paid the deposit through one of these two methods. In this case, you should be glad that there are ways to reverse the process but more on that later.

Speaking from experience, some scammers will try to lure you with either competitive spreads or high leverage or both, the latter being a double-edged sword. Central Margins allegedly offered a spread of 0.3-0.4 pips for EUR/USD, which is nice and relatively low.

But the leverage for that major pair is unknown. The only disclosed leverage is for cryptocurrencies – 1:20. For a market so volatile, this could result in huge losses, hence why regulators imposed a limit of 1:2-1:5.

Explosive-proof LED strip light improves safety

The x-Glo IECEx range is purpose built to provide a high level of protection by encapsulating electrical ignitions inside the light.To get more news about led bar decor, you can visit htj-led.com official website.

Mineglow general manager Carinne Pater said the IECEx certified lighting protected workers from the risk of accidental ignitions of flammable or explosive materials.

"The best way to prevent explosions in high-risk industrial areas is to remove potential ignition sources," Pater said.

"Lights are one of the most common causes of explosion ignition. Our solution minimises risk by isolating and containing sparks within the strip to prevent explosions from escaping and potentially igniting the gases and particles in the atmosphere.

"The low-profile of our lighting solution also means that they can't be knocked and shatter. This greatly minimises the risk of an explosive reaction from spreading or igniting volatile substances in the area, so in terms of health and safety - the benefits are significant."The x-Glo explosive-proof LED solution is IECEx, ATEX and ROHS approved and certified for gas zones one and two, and dust zones 21 and 22.

The lights are fully encapsulated with silicone, making them resistant to dust, humidity, chemicals and extreme environmental temperatures without enabling the risk of an explosion.

Pater said the LED-strip design offered considerable benefits over conventional lighting and other explosive proof products through its flexibility, efficiency, durability and ease of deployment.

"This range is unique as it combines IECEx certified protection and peace of mind with all the benefits of premium, industrial-grade LED strip lighting," she said.

"Beyond energy efficiency alone, industrial-grade LED strip lighting is renowned for its flexibility to install quickly and easily in hard-to-reach places, is fully customisable in length and requires zero maintenance.

"Due to their flexibility, our lights are easy to install, which means they can be mounted to any surface - including curved surfaces and corners - to provide consistent lighting to illuminate large areas.

"A single strip of our lights runs up to 30 metres and can be powered with 24V, 36V or 48V - AC or DC - giving customers the option to choose the optimum level of illumination for their application."

Mineglow's explosive-resistant range has a 50,000-hour lifespan and can provide a daylight spectrum light in white 6500K for continuous lighting in hazardous areas and red, amber and green for emergency directional lighting for illuminating escape routes.

Pater said LED explosion-proof lighting solutions were quickly becoming a safer, more cost efficient and sustainable long-term solution to alternative complex lighting infrastructures, especially in the Asia Pacific region.

World’s first explosive-proof LED strip light improves safety

Hazardous area LED strip light specialist and largest trading partner of x-Glo Lighting, Mineglow, has launched the world’s first IECEx certified explosive proof LED strip lights in Oceania.To get more news about led neon strip light, you can visit htj-led.com official website.

Reducing the risk of explosions in gas and oil rigs, coal mines and other industrial applications, the x-Glo IECEx range is purpose built for environments where fire or explosion hazards exist due to flammable gases or explosive substances such as vapours, mists or dusts.Mineglow General Manager, Carinne Pater said the IECEx certified lighting improves health and safety by protecting workers from the risk of accidental ignitions of flammable or explosive materials.

“The best way to prevent explosions in high-risk industrial areas is to remove potential ignition sources,” Pater said.“Lights are one of the most common causes of explosion ignition. Our solution minimises risk by isolating and containing sparks within the strip to prevent explosions from escaping and potentially igniting the gases and particles in the atmosphere.

“The low-profile of our lighting solution also means that they can’t be knocked and shatter. This greatly minimises the risk of an explosive reaction from spreading or igniting volatile substances in the area, so in terms of health and safety – the benefits are significant.”

The x-Glo explosive-proof LED solution is IECEx, ATEX and ROHS approved and certified for gas zones one and two, and dust zones twenty-one and twenty-two.

The lights are fully encapsulated with silicone, making them resistant to dust, humidity, chemicals and extreme environmental temperatures without enabling the risk of an explosion.Pater said the LED-strip design offers considerable benefits over conventional lighting and other explosive proof products through its flexibility, efficiency, durability and ease of deployment.

“This range is unique as it combines IECEx certified protection and peace of mind with all the benefits of premium, industrial-grade LED strip lighting.“Beyond energy efficiency alone, industrial-grade LED strip lighting is renowned for its flexibility to install quickly and easily in hard-to reach places, is fully customisable in length and requires zero maintenance.

“Due to their flexibility, our lights are easy to install, which means they can be mounted to any surface – including curved surfaces and corners – to provide consistent lighting to illuminate large areas.Mineglow’s explosive-proof range has a 50,000-hour lifespan and can provide a daylight spectrum light in white 6500K for continuous lighting in hazardous areas and red, amber and green for emergency directional lighting for illuminating escape routes.

Pater said LED explosion-proof lighting solutions are quickly becoming a safer, more cost efficient and sustainable long-term solution to alternative complex lighting infrastructures, especially in the Asia Pacific region.

“With the increasing regulations on worker safety globally, we’re seeing a lot of growth in the explosive-proof lighting market. It’s fantastic that we can provide a flexible LED strip lighting solution that’s truly unique and purpose-built for harsh conditions.”

THE EASY TO USE CAVITYCOMFORT PUMP FOR FRESHLY MASHED ORGANIC SUSPENSIONS

The CC series was developed for harsh applications in which long downtimes for service and maintenance work are not acceptable – such as pumping freshly mashed organic suspensions, i.e. highly viscous media loaded with large quantities of fibrous solid matter.To get more news about magnetic drive pumps accessories, you can visit brysonpump.com official website.

The QuickService design is one-of-a-kind. Vogelsang has managed to decisively improve the tried-and-tested concept of the progressive cavity pump: Compared to conventional progressive cavity pumps, service and maintenance work is significantly quicker and takes up less space, because the innovative QuickService design means there is no need to disassemble parts of the pipe. All essential parts, including the gasket, can be quickly and easily changed, so the pump is soon operational again. Even the mechanical seal in the trusted Quality Cartridge design is easy to replace in the CC series.

At the same time, attention was paid to creating a sturdy and fault-resistant design; features that are essential for biogas plants: The large free passage is ensured over the entire length, preventing clogging and blockages caused by coarse disruptive matter such as foil residue and wood. The sturdy design of the drive line, including the cardan shaft, makes the progressive cavity pumps in the CC series ideal for high dry matter content and media loaded with foreign matter. This means that the unique overall concept of the CC series ensures long service lives, short downtimes for service and maintenance, and low operating costs for your biogas plants.

If a gap arises between rotor and stator due to wear in operation, the capacity drops. Whereas with conventional progressing cavity pumps, this often means a sudden drastic fall of the pump performance and the replacement of the rotor and stator, the HiCone solves this with axial readjustment of the rotor. The conical shape ensures the gap is regulated, as a result of which the pump is back to its original condition and the pumping capacity returns to 100 percent. Instead of the costly and time-consuming changing of parts, there is a quick and easy adjustment – during ongoing operation.

Combined with Vogelsang’s integrated QuickService concept, this means significantly reduced life-cycle costs for the user and higher pump availability, since there are no elaborate service deployments. If replacement is nevertheless necessary, the rotor-stator unit is swung out and can then be renewed either as a unit or individually. A wear-resistant sleeve, which does not need to be unmounted to change parts, protects the sturdy cardan shaft.

Thanks to the clever adjustment system, rotor and stator can be optimally positioned to each other according to operating parameters like pressure, temperature and viscosity. This results in lower power consumption, which reduces the electricity requirement. Wear is also reduced at the same time.

In addition, the HiCone’s automatic start-up saves power. The positioning of the rotor and stator in relation to each other is in such a way, that there is only minimal clamping between them. This means that a smaller motor is needed to ramp up the pump than in conventional progressive cavity pumps, which reduces the power requirement when starting the pump to a minimum. This increases the energy efficiency and reduces the costs for power electronics. The result is lower electricity costs and reduced procurement expense for users. The start-up process is fully automatic without the need for additional control. The clamping between the rotor and stator can be adjusted during the entire service life at the touch of a button or at the click of a mouse from the control room.

Progressive Cavity Pump Parts

ACCA Pumps manufactures, stocks, and distributes progressive cavity pump parts to fit nearly all manufacturers and their complete model series in today’s Market. Our knowledge of progressing cavity pumps and their required spare parts spans more than 2 decades. This expertise have let us the know how on material selection and performance for all applications of PC pumps. All of our spare parts come with a 2 year warranty against manufacturing defects and a performance commitment that our PC pump parts will meet and perform as Original Equipment manufacturers (OEM) parts. To get more news about progressive cavity pump, you can visit brysonpump.com official website.

Rest assure that ACCA Pumps is the premiere manufacturer and distributor of a full range of pump replacement parts. A key to our success in the replacement parts arena has been the versatility of our parts. That is, ACCA parts are manufactured to fit not only ACCA pumps but also Moyno®, Seepex®, Allweiler®, Netzsch®, Monoflo®, Roper® and liberty Process pumps. ACCA guarantees that replacement parts will meet or exceed performance standards for any pump on which they are installed. Our enhanced quality standards, interchangeable fit and competitive pricing will suit both your operations needs and your budget requirements. Our confidence in our products is not overblown – it is shared by our customers who have relied repeatedly upon ACCA for the best value in the industry.

Springer Parts carries Progressive Cavity Pump Replacement Parts and Progressive Cavity Pump Repair Kits for many brands, including Allweiller®, Moyno®, Seepex®, Tarby®. Our aftermarket parts and kits are competitively priced, typically 20-40% less than OEM. Performance specifications and warranty meet or exceed OEM.

We offer all the most common wear and repair parts, such as stators, stator supports, rotors, drive shafts, connecting rods, suction housings, suction bodies, reducers, and body supports gear joint kits.

Titan Capital Markets Review: Boris CEO trading bot Ponzi

Titan Capital Markets fails to provide ownership or executive information on its website.To get more news about titan capital markets review, you can visit wikifx.com official website.

Titan Capital Market’s website domain (“titancapitalmarkets.com”), was privately registered on March 31st, 2022.Yan doesn’t exist outside of Titan Capital Markets’ marketing. That said, some effort has gone into creating a bogus digital profile.

The campaign was put together by Naga DDB Tribal, a Malaysian marketing company.

I want to clarify that work is work and I’m not insinuating anything from the actor’s role. The takeaway is that “Klaus Huber” is being played by a Malaysian actor and doesn’t actually exist.Neither does Howard Yan but, other than him possibly being from Taiwan, was unable to find anything further.

Some of Titan Capital Markets’ videos are strange, like this Fulham Football club sponsorship promo.

Early Titan Capital Markets videos suggest initial promotion in south-east Asia. Since then recruitment anywhere outside of India appears to have collapsed.Today SimilarWeb tracks 100% of Titan Capital Markets’ website traffic as originating from India.

In an attempt to appear legitimate, Titan Capital Markets presents itself as an Australian shell company:The first level of the binary team houses two positions. The second level of the binary team is generated by splitting these first two positions into another two positions each (4 positions).

Subsequent levels of the binary team are generated as required, with each new level housing twice as many positions as the previous level.

Positions in the binary team are filled via direct and indirect recruitment of affiliates. Note there is no limit to how deep a binary team can grow.

At the end of each day Titan Capital Markets tallies up new fee volume on both sides of the binary team.Affiliates are paid 12% of fee volume generated on their weaker binary team side.

Once paid out on, fee volume is matched against the stronger binary team side and flushed.Titan Capital Markets represents it generates external ROI revenue via a “3-way arbitrage system”. This is the typical trading bot Ponzi ruse.

Titan Capital Markets fails to provide evidence it generates external ROI revenue, via a trading bot or any other means.

Being a passive investment opportunity, Titan Capital Markets is required to register with financial regulators and provide audited financial reports.

The only financial regulator Titan Capital Markets appears to have registered with is the Australian Securities and Investments Commission (ASIC).

XSocio Markets Review 2022

XSocio Markets is Fast-growing business takes its operations into lucrative global markets. XSocio Markets are looking to reach the next level of growth and we can do this by establishing a presence in new countries across the globe. Trade World’s Financial Instruments with World Leading Broker. Enhance Your Trading With XSocio Markets.To get more news about xsocio markets review, you can visit wikifx.com official website.

XSocio Markets is a trading name of XSocio Markets Ltd which is a company Registered in Saint Vincent and Grenadines under 24611 IBC 2018. Main office and registered: Suite 305, Griffith Corporate Centre, P.O.Box 1510, Beachmont, Kingstown, St. Vincent and the Grenadines

The most popular system for trading world’s markets across the globe. With our XSOCIO Markets Metatrader 4 software, you can use custom indicators and explore the world of automated trading using Expert Advisors.

MetaTrader 4 is a platform for trading Forex, analyzing financial markets and using Expert Advisors. Mobile trading, Trading Signals and the Market are the integral parts of MetaTrader 4 that enhance your Forex trading experience.

Most of XSOCIO clients will choose MetaTrader 4 to trade in the market. The platform offers ample of opportunities to traders of all skill levels: advanced technical analysis, flexible trading system, algorithmic trading and Expert Advisors, as well as mobile trading applications.

MetaTrader 5 delivers a powerful trading system with the Market Depth and a system of separate accounting of orders and trades. It supports both order accounting systems: the traditional netting system and the hedging option system. Four order execution modes are available to meet various trading objectives: Instant, Request, Market and Exchange execution. The platform supports all types of trade orders, including market, pending and stop orders, as well as trailing stop.

WikiFX Review: Why You Should Stay Away from QUOTEX?

I have been using quotex On date 16 dec i deposits 5000 inr through UPI on my quotex trading account but money got deducted from my bank account and didn't get credited in my trading account... ”The investor added: “i contacted support team but they didn't respond i writes them emails many times but no response at all but today they emailed me that my account has been banned because I contacted them...no help at all scam broker... please help me.”To get more news about quotex review, you can visit wikifx.com official website.

In fact, we received many requests to Wikipedia from investors who complained that Quotex was a complete scam, and that some investors are still completely caught up in the scam and don't even know it. We wrote this article today specifically for investors to draw attention to the fact that they should stay away from this brokerage because it really is a brokerage with a lot of dark history and illegal trading.

With such complex regulatory information, how should investors distinguish between good and bad traders? It's as simple as typing the name of the broker into WikiFX before you invest, you will see every aspect about this broker. WikiFX also provides a comprehensive score based on license, business, risk control, software and regulatory, which is benefit for investors to make judgments.

Now let's search “Quotex ” on WikiFX APP to find out more about this broker. WikiFX is an authoritative global inquiry platform providing basic information inquiry and regulatory license inquiry. WikiFX can evaluate the safety and reliability of more than 36,000 global forex brokers. WikiFX gives you a huge advantage while seeking the best forex brokers.

As you can see, based on information given on WikiFX(https://www.wikifx.com/en/dealer/1290453790.html), Quotex currently has no valid regulatory license and the score is rather negative - only 1.29/10! WikiFX will give brokers a composite score in five categories: license index, business index, risk control index, software index and regulatory index. Since Quotex does not have any supervision and does not obtain a regulatory license, the license index, risk control index and regulatory index all score 0, and the final total score is 1.29 (out of 10). Investors can see the overall situation through WikiFX, with higher scores indicating a more reliable broker.

Quotex has alleged to be registered in St. Vincent and the Grenadines, an offshore broker based in St. Vincent and the Grenadines – a favorite location for scam brokers. The local financial regulator, SVGFSA, has warned investors on multiple occasions that it does not regulate forex brokers and does not impose any sort of laws in the sphere of forex trading (this regulator only monitors the banking sector). For this reason, brokers registered in the country are far from the most reliable choice – since they do not have to meet any sort of requirements or answer to anybody.

From all the above information we can know that trusting a broker like QUOTEX Forex is simply not worth it – you will certainly end up robbed. WikiFX reminds you that forex scam is everywhere, you'd better check the broker's information and user reviews on WikiFX before investing.

You can also expose forex scams on WikiFX. WikiFX will do everything in its power to help you and expose scams, warn others not to be scammed. In addition, scam victims are advised to seek help directly from the local police or a lawyer.

WikiFX Review: Something You May Want to Know About V5 Forex Global

Registered in the United States, V5 Forex Global is a forex broker providing access to a massive financial market. With the V5 Forex Global platform, and traders can employ maximum leverage of 1:1000 on their positions. V5 Forex Global allows clients to get access to a series of market products, including Forex, BTC, Stock, Indexes, and Crude Oil.To get more news about v5 forex global review, you can visit wikifx.com official website.

Account Types

V5 Forex Global provides clients with two types of trading accounts, a real account and a demo account with virtual money of $100,000 in it.

Spreads & Commissions

V5 Forex Global says it provides spreads as low as 0.0 pips, which is not always true. Investors are strongly recommended to open a demo account first to test its trading environment and then to decide whether to switch to a real one or not.

Leverage

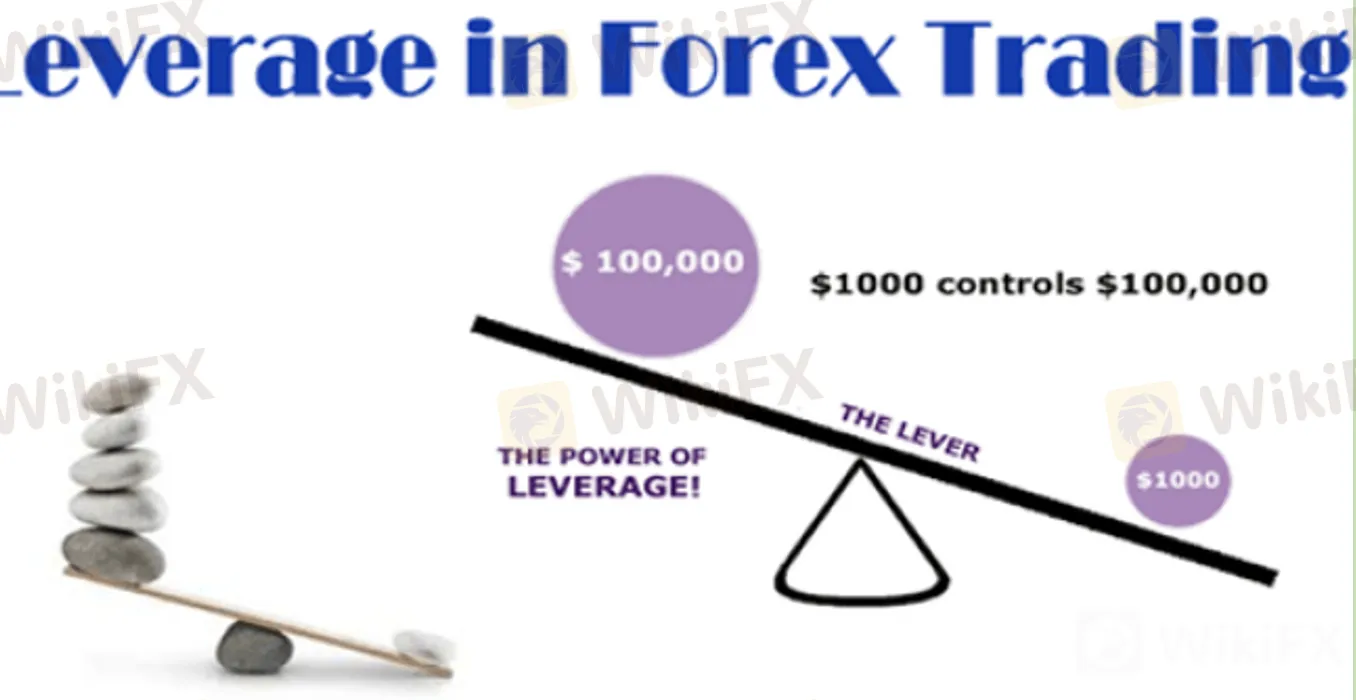

If on your V5 forex global trading account with the amount of $10,000, under the condition of the lever is 1000 times, and if you only want to use 10% of the account amount is $1000 for a margin call, you still can make a $100,000 ($1000x 100), because of the deal, the equivalent of v5 forex global provides you with similar s to the same credit card, and this is leverage role.

Since leverage can amplify both gains and losses, it can result in devastating losses for investors who lack experience. If you're just starting out in the trading world, it's best to stick with the lower size (no more than a 1:10).

Trading Platform

What V5 Forex Global offers is the Tradingweb for PC and Tradingweb for mobile.

Payment Methods

The minimum deposit is $50, and the minimum withdrawal is $10.V5 Forex Global allows its clients to make a deposit and withdrawal through Credit Cards and wire transfer, and this broker says it does not charge any fees for deposit or withdrawals.

Customer Support

Contact this broker using the following methods if you have any questions or problems with your trading:

Online Chat

Telephone: +44 7494 183618

Registered Company Address: 1312 17th St, Denver, CO 80202, United States

Risk Warning

Trading leveraged products such as forex, cryptocurrencies and derivatives may not be suitable for all investors as they carry a high degree of risk to your capital. Please ensure that your fully understand the risks involved, taking into account your investments objectives and level of experience.

Los Mejores Robots de Forex en 2023

All products and services featured are independently selected by WikiJob. When you register or purchase through links on this page, we may earn a commission.To get more news about costra-fx review, you can visit wikifx.com official website.

Si buscas convertirte en un trader de forex con mayor rentabilidad, o estás iniciándote y necesitas cierta orientación, nuestra reseña de los mejores robots de forex te ayudará a encontrar cuál es el adecuado para ti.

Los robots de forex utilizan un algoritmo para buscar operaciones rentables. Normalmente, puedes configurarlos para operar de manera automática (dentro de los parámetros acordados) o puedes introducir una operación manualmente.

Para llegar a ser un trader exitoso, tendrás que ser capaz de mantenerte al día con movimientos de los mercados de divisas, la economía mundial y las noticias, así como también necesitarás hacer uso de los conocimientos y datos históricos para predecir cuándo es el mejor momento para entrar o salir de una operación.

Al utilizar un robot de forex, automatizas esto y dejas lo emocional fuera del trading. Algunos de los mejores robots operan con ajustes de operación que pueden ser tan simples o complejos como se requiera, y toman el control total del proceso, creando la posibilidad de un ingreso pasivo del trading 24/7.

Los robots de forex no necesitan que tengas conocimientos o experiencia en el trading. La mayoría de ellos están listos para ser utilizados desde su instalación y ofrecen de todo, desde una funcionalidad básica de trading hasta una configuración totalmente programable, por esta razón, hasta un trader que tenga bastante experiencia puede beneficiarse de la automatización involucrada.

En el trading de forex no hay garantía de ganancias, el mercado puede ser volátil y hasta los robots más sofisticados (o el trader humano de forex más experimentado) pueden perder mucho dinero.

Si estás buscando un robot de forex, ten cuidado con los que dicen ofrecer enormes ganancias y no pueden proporcionar ejemplos en tiempo real de su rendimiento. Las reseñas de los usuarios siempre son una buena opción, al igual que las páginas web fiables de valoraciones.

Dejando a un lado las reseñas de los usuarios, échale un vistazo al uso en tiempo real de los brokers. Los sitios de verificación de terceros como myfxbook.com son siempre una buena opción para ver cómo están funcionando.

Los robots deben probarse. El utilizar los datos históricos para ver cómo van (lo que se conoce como backtesting) mostrará dónde tienen dificultades para predecir las tendencias y dónde funcionan bien.

Evidentemente, nos encontramos con muchas estafas en Internet y evitarlas puede resultar complicado. Aunque se han tomado todas las precauciones posibles para garantizar que los productos que se mencionan en la lista no son una estafa, no podemos asumir ninguna responsabilidad por las pérdidas financieras.

En WikiJob, no somos asesores financieros, y cualquier información proporcionada a lo largo de este artículo es simplemente para fines educativos. Siempre recomendamos que realice su propia investigación exhaustiva y la debida diligencia antes de tomar una decisión.

Lo más importante que debes recordar a la hora de elegir un producto es que no hay garantías con respecto a las ganancias en el trading de forex y criptomonedas. Debes evitar sitios que te aseguren ganancias sin ningún tipo de garantía de devolución de dinero, muchos de los robots más populares ofrecen al menos 60 días de trading y un reembolso completo, lo que hace que parezcan menos probables de ser una estafa.