User blogs

Iran army unveils 1st locally-made drone flight simulator

The first fully indigenous simulator for training drone pilots was unveiled in the presence of Iranian Army Ground Forces Commander Brigadier General Kioumars Heidari in the UAV unit of Hazrat Waliasr (AS).Get more news about Drone Simulation Company,you can vist our website!

At the event which was attended by army commanders and drone experts, general Heydari said, "Today, drones play an important and decisive role in promoting defensive and combat power of militaries, and it is a very valuable industry."

Stating that the army's ground forces have reached a favored position in the field of making drones, the commander added, "All borders of the country where the army's ground forces are deployed are monitored and controlled with reconnaissance drones."

The Commander of the Army Ground Forces considered the role of the UAV pilot training simulator as one of the important components in the training and education of UAV pilots and emphasized, "Today, we have reached a point of confidence that we can design and produce what is needed in the battlefield and this simulator is an example. It is one of the hundreds of completely locally produced military equipment and weapons in the army's ground forces, designed and produced by domestic specialists."

In the ceremony to unveil the simulator, several construction and welfare projects were inaugurated and put into operation in the UAV group of Hazrat Wali Asr (AS) in the presence of General Heydari.

Ford patents magnetic charging connector: MagSafe for EVs?

Ford has filed a patent application for a new type of EV charging connector based on a magnetic coupling.Get more news about led magnetic connector supplier,you can vist our website!

In the application, which was filed with the United States Patent and Trademark Office (USPTO) November 1, 2022, Ford describes using magnetic attraction to secure a charging connector with a charge port embedded in a vehicle's bumper.Ford envisions this magnetic charging connector being used with both EVs and plug-in hybrids, and with AC and DC charging stations. It also indicated that the magnetic connector could be installed on vehicles along with conventional charge ports.

Lacking a cable, this setup does require maneuvering a vehicle to align with the charging station. To make this less challenging, Ford said in the application that it would design in some degree of articulation to allow a hookup as long as the driver is relatively close to the target.

Ford does consider this to be a form of conductive charging, with a physical connection to transmit electricity, as opposed to the inductive charging exemplified by wireless charging systems. As with MagSafe, the magnetic system will help align connectors.

Getting rid of the physical connection is attractive, too. The recent Ram Charger inductive charging robot does without it, pressing up against a charging pad once aligned below the vehicle but relying on a magnetic field in between. The General Motors EV1 also used a unique Magne-Charge induction charging paddle.

Ford hasn't confirmed plans to use this novel charging connector in future production vehicles. Among the potential problems are the cosmetic (and parking vulnerability) challenge of integrating the charge port with a vehicle's bumper.

The desire to eliminate the fuss of handling charging cables has led to some interesting ideas, such as the snake-like robotic charger Tesla showed in 2015 and quietly shelved. The automaker now appears more focused on rallying other automakers to use its NACS connector, perhaps as part of a push to win federal money reserved for a national charging network. Aptera has confirmed plans to use the Tesla connector, but the automaker's pitch doesn't seem to have generated much interest from other firms.

Breakthrough EV battery pack could last 2 million kms

Chinese manufacturer Gotion High-Tech has announced a new battery pack will go into mass production in 2024 that it says will deliver range of up to 1,000kms for a single charge and could last two million kms.Get more news about Lithium Battery Pack,you can vist our website!

The company says the manganese doped L600 LMFP Astroinno will be able to do 4,000 full cycles at room temperature, and at high temperature will get 1800 cycles and over 1500 cycles of 18-minute fast charging.These incredibly high cycle numbers mean the battery could essentially last 2 million km before it starts to deteriorate. To put that into context, the average Australian car travels around 15,000 km per year so it would take 130 years worth of average driving to reach 2 million km mark.

Gotion High-Tech says the battery single-cell density is 240Wh/kg and that improvements in pack design have increased overall battery pack energy density to a point where 1000km range pack is possible with the highly durable chemistry.

“Astroinno L600 LMFP battery cell, which has passed all safety tests, has a weight energy density of 240Wh/kg, a volume energy density of 525Wh/L, a cycle life of 4000 times at room temperature, and a cycle life of 1800 times at high temperatures,” said executive president of the international business unit of Gotion High-Tech Dr. Cheng Qian.

The the volumetric cell to pack ratio has reached 76% after adopting the L600 cell, and the system energy density has reached 190Wh/kg, surpassing the pack energy density of current mass-produced NCM (Nickel Cobalt Manganese) cells.” said Dr Cheng.

“In recent years, lithium iron phosphate (LFP) technology has regained the recognition of the market with market share continuing to increase.

“Meanwhile, the energy density growth of mass-produced LFP batteries has encountered bottlenecks, and further improvement requires an upgrade of the chemical system, so manganese doped as called lithium iron manganese phosphate (LMFP) was developed.” said Dr Cheng.

According to Dr Cheng, Gotion High-Tech has solved the challenges of Mn dissolution at high temperatures, low conductivity and low compaction density through utilising co-precipitation doping encapsulation technology, new granulation technology and new electrolyte additives.

Benefits of BorSafe™ Super Low Sag PE100-RC pressure pipe

Borealis announces that Politejo, a leading global pipe manufacturer based in Portugal, has selected the new Super Low Sag (SLS) black polyethylene PE100-RC (resistant to crack) pressure pipe material for use in a major pipeline project comprising onshore and offshore sections in the Galicia region of northern Spain. The project is one example of how Borealis is using its step-change innovations to enhance the sustainability of pipe infrastructure by making pipes safer, more robust, and durable. By designing pipe materials with eco-efficiency and recycling in mind, Borealis is closing the loop on plastics circularity.Get more news about Hdpe Pe100 Granule,you can vist our website!

The new pipe material is the recently launched BorSafe™ HE3490-SLS-H. Its tailored polymer architecture and low melt flow rate (MFR) enable the production of pipe with high wall thicknesses while counteracting the “sagging phenomenon” characteristic of other conventional materials used in the pipe extrusion process. Sagging refers to the tendency for a hot melt (being extruded from the pipe extrusion die) to flow downward due to the force of gravity, resulting in uneven wall thickness and distribution. The low sag property of this resin makes the production process more efficient, with faster start-up in reaching the required dimension tolerances for pipe diameter and wall thickness. Another benefit is the reduction of scrap rates and overall waste avoidance.

For Politejo’s large-diameter pipeline project in Spain, pipes with diameters of 900 mm and 1100 mm will be used in the onshore section, while a larger number of pipes with diameter of 1400 mm and 60 mm wall thickness will be used in the offshore section, where submersed installation demands especially high quality and long material lifespan.

The very high Slow Crack Growth (SCG) resistance of BorSafe HE3490-SLS-H translates into faster installation and cost efficiency. Faster installation times can be realised because the robustness of the pipe allows for installation without sand-bedding around it. For drinking water applications, the new and improved formulation offers extra assurance of purity for the safe transport of potable water. Finally, design for eco-efficiency in the spirit of means that this material solution boasts an expected lifespan of over 100 years, and is fully recyclable.

BorSafe HE3490-SLS-H can be produced using a grade from the portfolio of circular polyolefins. In future, resins from the transformational portfolio of chemically recycled solutions can also be selected for pipe applications.

Both the Bornewables and Borcycle C grades are composed of ISCC PLUS-certified (International Sustainability & Carbon Certification Plus) feedstock produced using the mass balance method; both enable significant CO2 footprint reductions when compared to the use of fossil fuel-based feedstocks.

WHAT IS A SPIRAL WOUND GASKET?

A Spiral Wound Gasket (SWG) is a type of industrial gasket that is widely used in high-temperature, high-pressure, and corrosive environments. It consists of a V-shaped metal strip and a softer filler material that is wound in a spiral fashion to create a resilient sealing surface. This article will discuss the construction, types, advantages, applications, factors to consider, installation, maintenance, challenges, and importance of Spiral Wound Gaskets.Get more news about Ptfe Gland Packing,you can vist our website!

The construction of a Spiral Wound Gasket comprises four main parts: the outer ring, inner ring, winding strip, and filler material. The outer ring is made of carbon steel or stainless steel, and it acts as a compression stop to prevent over-compression and gasket blowout. The inner ring is made of the same material as the winding strip, and it provides additional support to the gasket. The winding strip is typically made of stainless steel or other alloys and is wound in a spiral fashion to create the gasket's sealing surface. The filler material is placed between the winding strip to enhance the gasket's sealing properties.

Graphite: Graphite is a popular filler material due to its excellent thermal and chemical resistance. It is often used in high-temperature and high-pressure applications, such as in the oil and gas industry.

PTFE: PTFE (Polytetrafluoroethylene) is another popular filler material known for its chemical resistance and low coefficient of friction. It is often used in applications that require resistance to corrosive chemicals.

Ceramic: Ceramic filler material is ideal for applications that require high-temperature resistance and good electrical insulation. It is often used in the chemical and petrochemical industries.

Mica: Mica filler material is known for its excellent heat resistance and is often used in high-temperature applications.

Non-Asbestos: Non-asbestos filler materials are used in applications that require good chemical resistance without using asbestos.

Excellent Sealing Performance: Spiral Wound Gaskets provide a tight seal and are suitable for high-pressure applications.

High Temperature and Pressure Resistance: Spiral Wound Gaskets can withstand high temperatures and pressures, making them suitable for use in demanding applications.

Resistant to Corrosion and Chemicals: Spiral Wound Gaskets are resistant to most chemicals and are suitable for use in corrosive environments.

Durable and Long-Lasting: Spiral Wound Gaskets are durable and long-lasting, reducing maintenance costs and downtime.

THE CRUCIAL ROLE OF RIOT HELMETS FOR POLICE

In today’s dynamic and ever-changing world, law enforcement agencies face numerous challenges in maintaining order and ensuring public safety. Among the essential tools at their disposal are riot helmets, which play a crucial role in protecting police officers during potentially volatile situations.Get more news about Anti Riot Helmet,you can vist our website!

Riot helmets serve as a vital component of police officers’ personal protective equipment (PPE), offering critical head and face protection in riotous or confrontational scenarios. These helmets are specifically designed to withstand various hazards encountered during civil unrest, including thrown projectiles, chemical irritants, and physical assaults. By providing a physical barrier, riot helmets reduce the risk of head injuries, skull fractures, and lacerations, thereby ensuring officers can perform their duties with confidence and minimal risk to their well-being.

Our PROTEC-X Riot Helmet is one of our most popular riot helmets for anti-riot operations. Paired with our TURBO-X Riot Suit, this helmet is strong, secure, and tested to NIJ 0104.02 anti-impact standards. It includes a strong neck guard to help protect against neck threats, an the thick visor also includes a fluid guard to help protect against the entrance of liquids or bodily fluids that may be thrown at an officer wearing the riot helmet.

Riot helmets not only provide physical protection but also exert a psychological impact on both law enforcement personnel and the public. When officers wear riot helmets, it sends a clear visual message that they are prepared to maintain order and respond to potential threats. This visible deterrent effect can dissuade individuals from engaging in violent or disruptive behavior, helping to de-escalate tense situations before they spiral out of control. By projecting an image of authority and readiness, riot helmets contribute to a sense of security and discourage the escalation of violence.

One of ExecDefense helmets that is popular for high-tactical riot operations is our TERMINATOR-X Riot Helmet. This helmet is equipped with a strong steel face cage to help reduce the impact of blunt objects to the face, and it also includes a strong fluid guard gasket on the top of the visor. The neck protector is removable (for easy cleaning) and the visor is standardly treated with an anti-fog treatment. This helmet is popular to be paired with the ExecDefense PROTEC-X gas mask (front face style) along with EDI’s RUB-X Riot Shield.

Public trust and confidence in law enforcement are paramount for effective community policing. Riot helmets play a role in preserving this trust by ensuring that officers can effectively perform their duties while minimizing personal harm. When the public witnesses police officers equipped with protective gear, it conveys a sense of professionalism and commitment to public safety. By prioritizing officer safety, riot helmets underscore the principle that law enforcement agencies value the well-being of their personnel, further enhancing public trust and cooperation.

Although riot helmets are an essential part to an officer’s gear bag, it’s important that riot helmets are used in conjunction with other protective equipment to help ensure officer safety. Riot suits, riot shields, and batons, are just the basics. If there are more intense crowd control operations, then gas masks, handcuffs, and other tools may be required.

Legislature plans restrictions on electronic pull-tabs

A finish-line addition to this year's tax bill will clamp down on electronic pull-tabs, which have become a cash cow in Minnesota since they were legalized to pay for the Vikings stadium in 2012.Get more news about china pull tab tickets,you can vist our website!

The session's big tax bill will put new restrictions on the games, but backers say that'll be at the expense of charities.

Electronic pull-tabs were legalized to pay the taxpayer's share of a new NFL stadium. After initially foundering, e-pull-tabs have become a $6.3 million-a-day business in Minnesota. They paid off the stadium debt and filled state tax coffers.

But lawmakers have put the brakes on what has been exponential growth of the games. A provision in this year's tax bill will prohibit some of their supposedly most attractive features, so-called “open all” games that allow a single touch to reveal all of a player's prize chances at once, as well as second-chance provisions.

It's the latest skirmish in the long-running battle over gambling in Minnesota and who runs it.

“The fact of the matter is that the courts of have ruled that these things cannot mimic slot machines,” said Gov. Tim Walz.

Tribal gaming agreements give them the right to certain forms of gambling, like slot machines. But the difference with e-tabs can be subtle — even too subtle for some people.

This year's tax bill will draw that line more clearly, although the consequences are a matter of fierce debate as lawmakers wrap up their annual session today.

Electronic pull-tab fans say the changes to the way they're played will make the games less attractive and be a serious setback for state charities and the more than $120 million a year that they give away.

“We talk about e-tabs doing the great things for our community. St. Paul Park food shelves that we're giving thousands of dollars to a year. Food recovery. We're supporting our communities,” said Ray Kane, gambling manager for the Lions Club in St. Paul Park and Newport.

The electronic games also attract younger and more female players, keeping Minnesota's traditional charitable gambling industry alive, according to Jon Weaver.

“This is a very social activity. You go to the bar, you're with your friends you're with your spouse, you play these games. You're there not to win a million dollars. You're there to have fun, hang out and socialize,” Weaver said.

Brian Mast: ‘Proud’ to be only congressman to have worn US Army

The anti-Israel activists draped in Palestinian flags in the tony Beacon Hill neighborhood who yelled at and taunted the U.S. Army veteran and his family in Boston’s Public Garden couldn’t have known that they’d be partly responsible for shaping one of Israel’s staunchest defenders in Congress.Get more news about military mast,you can vist our website!

It’s not hard to figure out that I’m a veteran. I don’t have any legs, and I wear a hat that says ‘Army Ranger,’ so most people with half a mind can put two and two together,” Rep. Brian Mast (R-Fla.) told JNS.

At the time, Mast had retired in 2012 after a dozen years of service as an explosive specialist who lost both legs to a bomb in Afghanistan in 2010. He was studying at Harvard University, and he and his then-pregnant wife, Brianna, and their two sons (they now have four children) would go to the picturesque Public Garden in the evenings so the kids could ride their bikes and play in the grass.

The protesters, who showed up weekly or so, decided to yell things like “You’re the big Satan” and “You’re a pawn” at Mast, the congressman told JNS. Mast, who is Christian, hadn’t followed Israel closely at the time, although he saw references on the news.

These people, who were out there to protest Israel, all of a sudden wanted to pick a fight with me, which is just fine. I don’t mind getting into verbal or physical confrontations with other people,” Mast, 42, a fourth-term congressman representing Florida’s 21st District, told JNS.

“It was the first time this fight had really ever been thrown at my feet in that way, where people were trying to drag me into what I was seeing in the news,” he said.

Mast found their verbal assaults hypocritical. He told JNS that he had said of the attacks on Israel in one of his Harvard classes, “If it was Mexico or Canada or some Caribbean country firing rockets into America, then guys like me would go and kill them, and every American would be proud of us for doing so.”

He came home after enduring the taunts one night and told his wife, “I don’t know what it’s going to look like, but I’m going to find a way, and I’m going to go and show my support for Israel. I’m going to go out there and find a way to fight against this hypocrisy.”

What Is NAD+ And Can It Really 'Reverse' Aging?

There’s been chatter on TikTok about a “miracle drug” called NAD+ that can allegedly reverse or “cure” aging. But the reality is a lot more complex than TikTok has made it to be.Get more news about High Purity Nad Powder Supplement,you can vist our website!

NAD+, or nicotinamide adenine dinucleotide, is an essential coenzyme in regulating metabolism, longevity, DNA repair, and the immune system. A deregulation of NAD+ levels is associated with signs of aging, metabolic diseases, neurodegeneration, and cancer.1

Preliminary studies in mouse models have shown that increasing supplements of NAD+ precursors—including nicotinamide mononucleotide (NMN) and nicotinamide riboside (NR)—may result in health benefits and delayed signs of aging.2

Human bodies are like electric cars in the sense that they run on high-energy electrons, and these electrons need a way to travel through the body, according to Charles Brenner, PhD, the researcher who identified NR as an unanticipated vitamin precursor of NAD+.

In cars and other devices, the electrons flow on copper wires. In our bodies, high-energy electrons are carried by NAD coenzymes. NAD is vital to cellular function and allows us to convert our food to energy and to build and repair our bodies,” Brenner told Verywell.

NAD+ is neither a drug nor a miracle, he explained. But it has become a big area of focus in the healthy aging space because it declines with age and exposure to certain stressors, such as sedentary lifestyles, high fat/sugar diets, excessive alcohol intake, and immune challenges. This decline in NAD+ has been observed in people with aging-related diseases.

Current research suggests that NAD+ levels can be raised by taking NAD+ precursors or boosters, Brenner added. NR, which was discovered by Brenner, is currently one of the most well-researched and efficient precursors of NAD+. NR is being studied in clinical trials that include research on heart disease, Alzheimer’s disease, kidney injuries, aging, and chemotherapy.3

“Multiple conditions of metabolic stress including overweight, alcohol use, DNA damage, sunlight exposure, infection, inflammation, and postpartum disturb the NAD system,” Brenner said. “When the NAD system comes under attack, NR is powerfully protective of tissue functions and metabolism.”

In animal models, studies have shown that stimulating NAD+ with NMN or NR can extend healthspan—defined as years lived in good health—and reduce premature aging, according to Renae Thomas, MD, MPH, a physician certified in family medicine, public health, and general preventive medicine.

Human trials so far have shown that NAD+ supplementation may improve exercise performance in older adults,4 increase insulin sensitivity, and provide anti-inflammatory effects, Thomas added.

“Because NAD+ plays a vital role in many of the biological processes in humans associated with aging and DNA repair, it is definitely a very interesting area of research. We just need more data to support the claims and hype around it at this time,” she said.

It’s important to note that taking supplements is not the only strategy to increase NAD+ levels, Thomas added. Many healthy human lifestyle behaviors, such as exercise, quality sleep, and not eating excessive calories, are also associated with increased levels of NAD+ and likely the associated health benefits.

However, NMN is currently not allowed to be marketed in the U.S. because the FDA in 2022 said this ingredient no longer met its definition as a dietary supplement. While these NAD+ supplements may provide some benefits, Thomas said it’s best to speak with your physician before trying them.

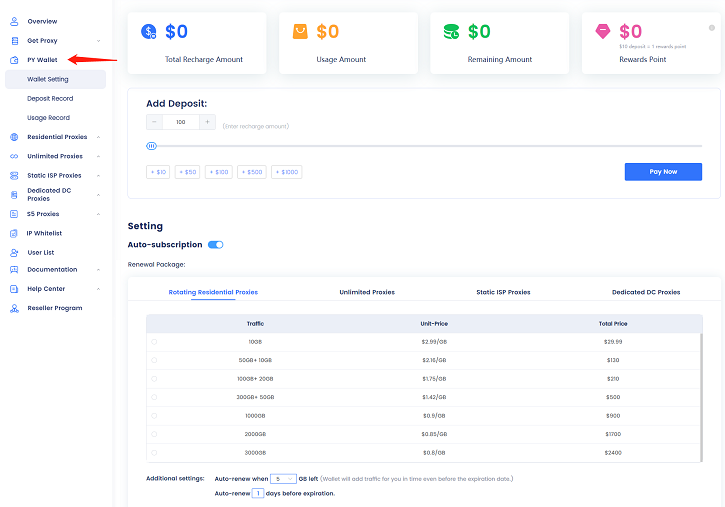

The Ultimate Guide to Buy a Proxy Server

The proxy server receives the request from the browser immediately once somebody requests a specific facility or service, like gaining access to a site.To get more news about access ip, you can visit pyproxy.com official website.

The proxy server eventually transmits the request made by the customer to the target server, gets the reply, and finally returns it to the customer.

A proxy server is an effective tool in today’s digital world, when secure, confidential, and unlimited surfing remains of the biggest significance.

Well buy proxy server is a smart move either you’re a user seeking protection for your online activity or a corporation looking to improve its data security procedures.Let’s explore inside the globe of proxy servers, discussing proxy servers, their advantages and detailing key points to bear in mind before making a purchase.

Having a proxy is mainly used to offer a number of features and advantages, such as:

By hiding the client’s IP address, proxies can increase the privacy and security of their online conduct. The proxy server serves as a middleman and hides the client’s IP address from the server that is being accessed to provide anonymity.

Proxy servers can be implemented to uphold privacy regulations, enabling businesses, institutions of higher learning, and other firms to limit access to particular websites or categories of information in accordance with predetermined guidelines.

Using proxy servers, organizations and parents can impose content filtering regulations and limit access to particular websites or categories of content. This can help to provide a safer and more regulated internet environment in locations like homes, offices, and educational centers.

The local copies of websites, images, and other types of information can be stored by proxies. The proxy can provide sufficient proof stored in its cache when many clients make the same request, saving traffic and enhancing instantaneous responses.

By dividing new client requests via several servers, proxies may moderate the workload and guarantee the best possible speed and availability.

By serving as a barrier among the client and the target server and examining and screening traffic that arrives for potential risks like viruses or illegal requests, proxies can add an extra layer of protection.

Using proxies, people can get around geolocation limitations enforced by some websites or internet services. People are able to utilize services or content which could have been prohibited due to their geographical location via a connection to a proxy server in another region.